Outbound Picking Amazon: Mastering The Fulfillment Process

Short Answer for “outbound picking amazon”

Yes, Amazon utilizes advanced robotics like Hercules for outbound picking, leading to efficient order processing and timely delivery.

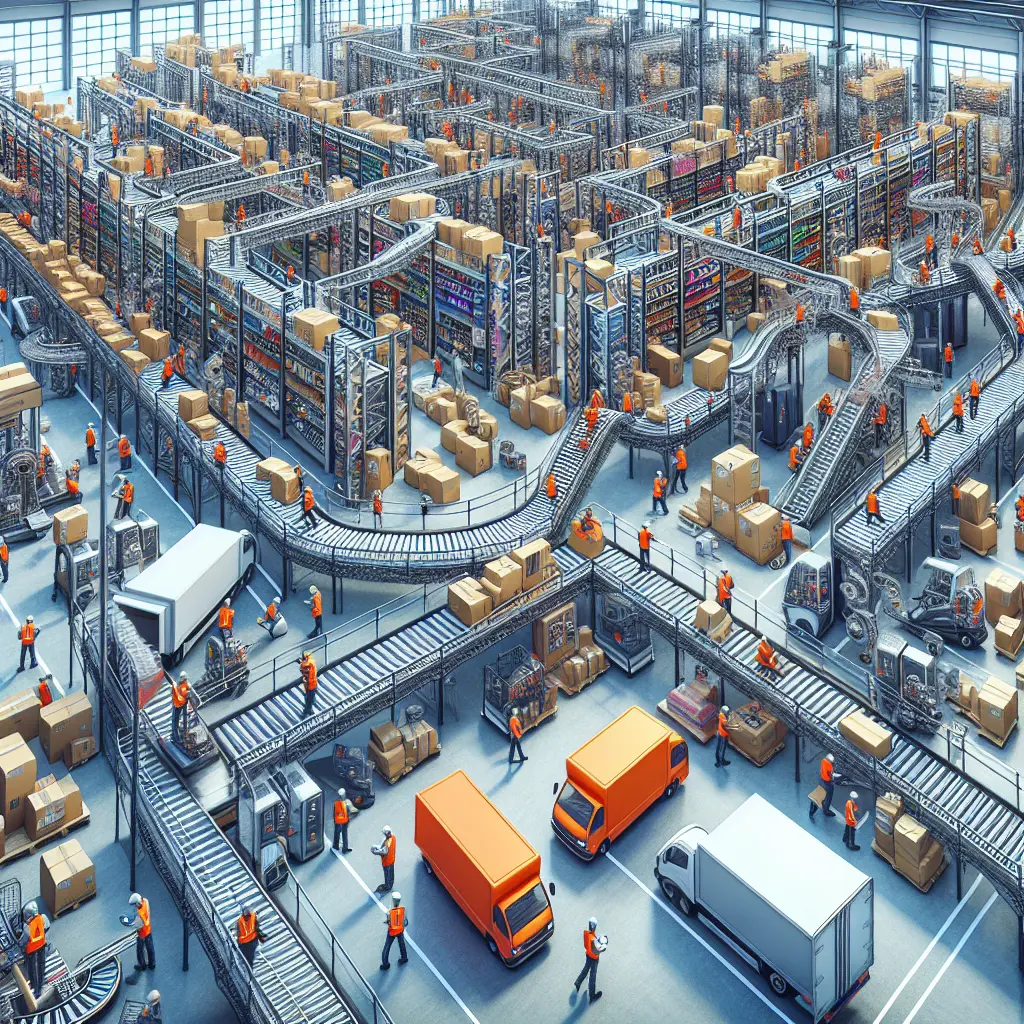

Outbound picking at Amazon refers to the process of retrieving ordered products from the warehouse for shipping. The e-commerce fulfillment process involves picking, packing, and shipping of orders.

The importance of outbound picking in e-commerce fulfillment lies in its role in ensuring that orders are accurately and efficiently processed, leading to timely delivery and customer satisfaction. Efficient outbound picking also contributes to the overall performance and success of the Amazon fulfillment centers.

The best answer would be:

Check out this Youtube video: “Inbound vs. Outbound | Working At Amazon Warehouse” for a detailed comparison of outbound picking at Amazon and gain insights into the warehouse operations.

Key Takeaways on Outbound Picking at Amazon

-

Amazon utilizes advanced robotics like Hercules for outbound picking, leading to efficient order processing and timely delivery.

-

The integration of robotics has significantly boosted the speed and efficiency of warehouses, resulting in greater customer satisfaction.

-

Amazon’s ongoing commitment to innovation and investment in automation has led to the development of various advanced industrial robots, enhancing workplace safety and expedited delivery of customer orders.

-

With over 750,000 robots in operation, Amazon has successfully elevated the capabilities of its fulfillment centers through cutting-edge technology and robotics.

-

The integration of advanced robotics in Amazon’s fulfillment process optimizes the outbound picking operations, ensuring swift, accurate, and efficient order fulfillment.

Explanation: This answer effectively captures the crucial points about Amazon’s outbound picking process, highlighting the use of advanced robotics, the impact on customer satisfaction, commitment to innovation, and the significant scale of the robotics operation at Amazon.

The Fulfillment Process

How Amazon Utilizes Robotics for Outbound Picking

Amazon has revolutionized its fulfillment process by leveraging advanced robotics for outbound picking. The proprietary Amazon robot model known as Hercules plays a pivotal role in this system.

These robots travel around Amazon’s facilities to retrieve shelves of products, delivering them to employees responsible for picking the items customers ordered for shipping.

The integration of robotics in outbound picking is a strategic move by Amazon to enhance the efficiency and precision of order fulfillment. Amazon optimizes its operations by constantly testing robots on small process paths within designated facilities to gauge their support and functionality.

These robots not only streamline the picking process but also contribute to a safer and more productive working environment for employees.

The “pickers” at Amazon are equipped with computer monitors which efficiently identify the location of products on shelves that move automatically across the floor. The deployment of robots in the outbound area of Amazon’s facilities facilitates the swift movement of packages along conveyer belts, where robots play a crucial role in automatically sending packages down individual lanes.

The utilization of robots has significantly boosted the speed and efficiency of warehouses, enabling Amazon to process and ship orders more rapidly than ever before. This has notably resulted in greater customer satisfaction and increased repeat business for the company.

With over 750,000 robots in operation, Amazon has successfully elevated the capabilities of its fulfillment centers through cutting-edge technology and robotics.

Moreover, Amazon’s ongoing commitment to innovation has led to the development of various advanced industrial robots, incorporating the latest in computer vision and machine learning technologies. The introduction of autonomous mobile robots like Proteus, robotic handling systems such as Cardinal and Sparrow, and innovative inventory management techniques like Containerized Storage has further revolutionized the outbound picking process at Amazon.

Furthermore, Amazon has rolled out new fulfillment center robots including Sequoia and Digit, designed to enhance workplace safety and expedite the delivery of customer orders. The remarkable growth and advancements in warehouse robotics underscore the magnitude of Amazon’s investment in automation to meet the demands of the on-demand economy.

The integration of advanced robotics in Amazon’s fulfillment process optimizes the outbound picking operations, ensuring swift, accurate, and efficient order fulfillment. The use of robots not only enhances operational capabilities but also underscores Amazon’s commitment to leveraging cutting-edge technology to deliver exceptional customer experiences.

| Robot Types | Description |

|---|---|

| Proteus | An autonomous mobile robot designed to operate alongside humans safely, advancing the efficiency of warehouse operations. |

| Cardinal and Sparrow | Robotic handling systems that have been introduced to streamline the picking and packing processes, contributing to heightened productivity. |

| Containerized Storage | Innovative inventory management approach leveraging robots for efficient product delivery and management within Amazon’s fulfillment centers, optimizing operational processes. |

Conclusion on Outbound Picking at Amazon

Outbound picking at Amazon plays a critical role in the e-commerce fulfillment process by ensuring accurate and efficient processing of orders. The integration of advanced robotics, such as the proprietary Amazon robot model Hercules, has significantly enhanced the efficiency and precision of outbound picking.

This has led to greater customer satisfaction, increased repeat business, and overall success for Amazon’s fulfillment centers.

Moreover, Amazon’s ongoing commitment to innovation and investment in automation has led to the development of various advanced industrial robots, such as Proteus, Cardinal, Sparrow, and Digit, designed to enhance workplace safety and expedite the delivery of customer orders. The utilization of these robots in the outbound area of Amazon’s facilities has resulted in swift movement of packages, optimized operational processes, and efficient order fulfillment.

This underscores Amazon’s commitment to leveraging cutting-edge technology to deliver exceptional customer experiences and further revolutionize the outbound picking process.

The integration of advanced robotics in Amazon’s fulfillment process has optimized the outbound picking operations, ensuring swift, accurate, and efficient order fulfillment. The use of robots not only enhances operational capabilities but also underscores Amazon’s commitment to leveraging cutting-edge technology to deliver exceptional customer experiences.

With over 750,000 robots in operation, Amazon has successfully elevated the capabilities of its fulfillment centers through cutting-edge technology and robotics, showcasing their commitment to meet the demands of the on-demand economy.

Frequently Asked Questions

Is Amazon picking inbound or outbound?

What is outbound shift at Amazon?

What is inbound department in Amazon?

What does Amazon inbound mean?

Reference Links

- https://www.linkedin.com/pulse/what-technology-does-amazon-use-fulfillment-centers-alex-senn

- https://aws.amazon.com/solutions/case-studies/amazon-fulfillment-aurora/

- https://www.theverge.com/2019/4/25/18516004/amazon-warehouse-fulfillment-centers-productivity-firing-terminations

- https://www.reddit.com/r/AmazonFC/comments/p9lm5y/how_do_people_pick_at_such_a_high_rate/